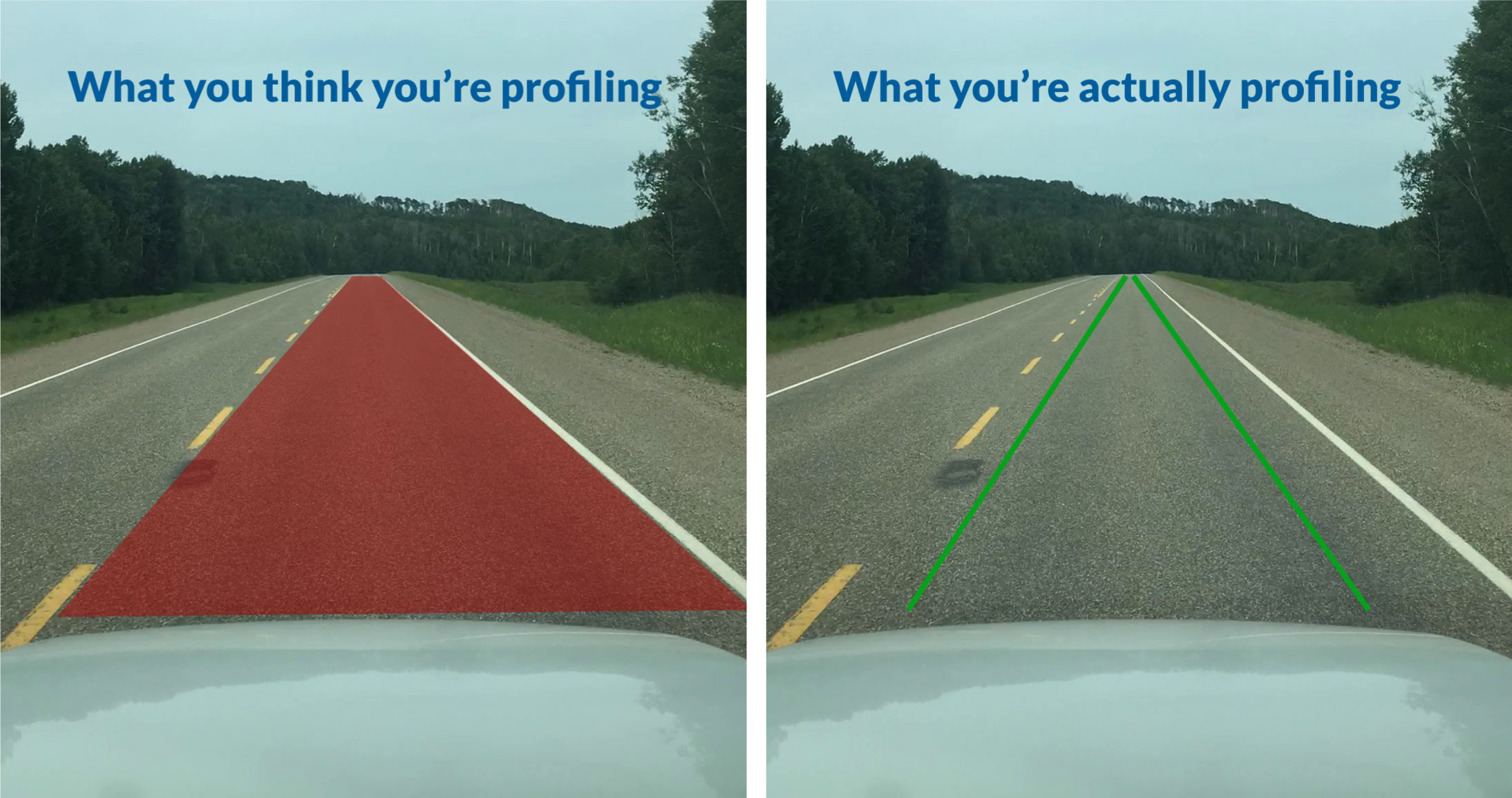

What a single IRI run tells you about a road surface is one of the most common misconceptions we encounter. Regardless of whether people are completely new to road condition data collection, or they have been operating a laser profiler and interpreting the data for 20 years the same is usually true: people often think that the IRI data for a single pass on a section of road represents the roughness of the entire width of the lane you are driving in.

In reality, the IRI data collection equipment you are using is only measuring the road profile of the thin path the sensor travels. Naturally, each path has a different profile which produces different IRI values. If there is significant lateral variability in the road surface condition, there will be higher variability between IRI runs.

The largest source of variability between IRI runs is the road surface itself.

This is important to understand in two situations:

- Collecting IRI for asset management purposes

Traditional profilers used to collect IRI for asset management projects generally do one pass in one lane in one direction and consider the reported IRI to be the roughness of the entire width of the road. In many cases, roads have a high level of lateral variability, therefore doing one single pass may not be enough to get an accurate representation of the actual roughness of the full width of the road.

- Comparing two IRI data collection technologies

If you are attempting to compare IRI data collection technologies (TotalPave IRI vs a traditional profiler for example), you must control for random sources of error in your experimental setup. The largest source of random error is lateral variability in the road surface itself.

We will elaborate on both of these points in further detail below, but first, let’s start off with some background:

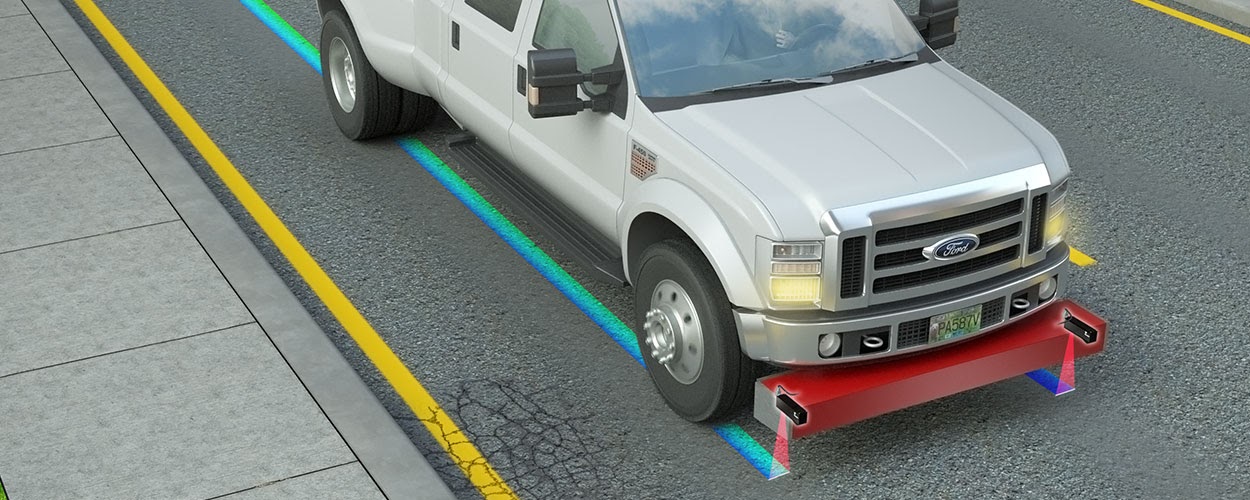

Common bumper mounted laser profilers have two sensors, one approximately aligned with the right wheel well and the other approximately aligned with the left wheel well. When you drive a section of road while recording data with this setup, you get two IRI values. Each IRI value is calculated using the profile collected from each sensor, and each profile is representative of whatever path or slice of road the sensor travelled while recording. Here is a graphic from LMI Technologies that displays the two sensor setup described above:

Imagine if you connected a can of spray paint to the IRI sensor to mark the sensor’s path as you drive, the IRI value reported from each sensor would be calculated using the profile obtained from those thin slices of road, not the entire lane. The same is true with a smartphone based platform like TotalPave, except the IRI sensor is your phone mounted to the windshield. Here is a graphic of what that might conceptually look like for a traditional laser profiler:

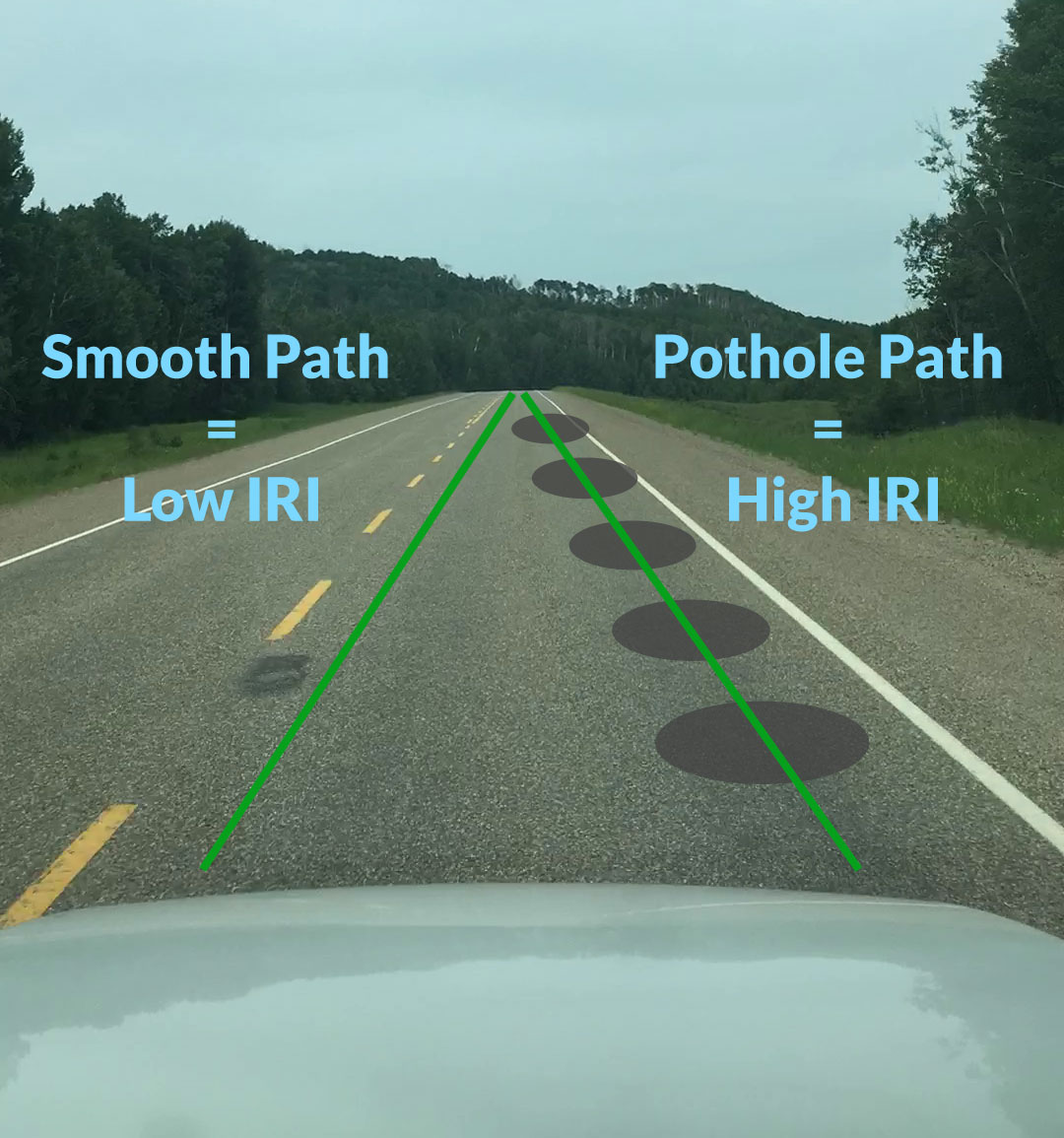

Now imagine if there was a series of potholes in a perfect line all the way up the right side of the lane, while the left side of the lane was perfectly smooth. The right wheel path sensor in this case would read extremely high IRI values, because the path the sensor took would include the series of potholes. The left wheel path sensor would produce a low IRI value because that side of the lane was relatively smooth.

In the real world you would very rarely see a perfect line of potholes in one wheel path, and absolutely no distress in the other. Distress propagates randomly over the surface of the road producing drastically different IRI results depending on the path you drive. Even minor variations in path driven could mean you hit different distresses between runs, producing a different longitudinal profile each time resulting in a different IRI value within the same lane. In the image below we’ve randomly drawn some potholes, longitudinal/transverse cracking, and alligator cracking to show what might happen in the real world:

The table below presents real data to show how much lateral variability there can be on a road surface in the wild. The data was collected using a bumper mounted Class 1 laser profiler manufactured by Surface Systems & Instruments. The profiler had one sensor recording the profile of the road over the right wheel path, and one sensor recording the profile of the road over the left wheel path, similar to the setup described above. The IRI data was reported in 100m intervals.

| 100m Seg Start | 100m Seg End | IRI Wheelpath 1 | IRI Wheelpath 2 | Percent Diff |

| (m) | (m) | (m/km) | (m/km) | % |

| 0 | 100 | 5.74 | 6.99 | 19.7% |

| 100 | 200 | 24.16 | 8.01 | 100.4% |

| 200 | 300 | 3.48 | 6.61 | 62.0% |

| 300 | 400 | 5.00 | 5.02 | 0.3% |

| 400 | 500 | 2.99 | 3.82 | 24.3% |

| 500 | 600 | 3.67 | 4.84 | 27.4% |

| 600 | 700 | 8.11 | 5.74 | 34.3% |

| 700 | 800 | 5.83 | 7.16 | 20.5% |

| 800 | 900 | 6.18 | 5.83 | 5.9% |

| 900 | 1000 | 4.45 | 4.64 | 4.1% |

| 1000 | 1100 | 7.94 | 7.07 | 11.7% |

| 1100 | END | 4.45 | 4.36 | 2.1% |

| AVERAGE | 6.83 | 5.84 | 26.1% |

Notice that only three of the IRI values from corresponding wheel paths were within 5% of each other and the average percent difference between the two wheel paths was over 25%. The most extreme gap was observed on the 100m to 200m segment, where the difference between the right and left wheel path IRI readings was over 100%.

These tests do not show that the profiler itself was faulty in any way, in fact it had just recently been calibrated and was confirmed to be in good working order. What we are observing here is that there is extreme lateral variability on the road surface. Even though the two paths being reported are not that far apart, they still produce dramatically different IRI values. If multiple runs were done on this section of road, you would not expect the IRI values between runs to necessarily correlate even if you attempt to drive the exact same path because minor differences in path driven in this case could produce different roughness levels.

Another way to think about this is that you are essentially sampling a thin slice of road every time you do an IRI run. As mentioned above, an individual IRI run does not represent the roughness of the entire width of the lane you are driving in. With that said, you can drive a lane multiple different times to obtain IRI values representing the different paths driven, each IRI value can be averaged together to get a more accurate representation of the overall roughness of the entire width of the lane. The more runs you do, the more accurate overall average you will get, but the number of runs you must perform to get a stable average is dependent on how much lateral variability there is in the lane.

The driver of this lateral variability is distress on the surface of the road. Higher distress roads will have higher lateral variability, producing larger differences between individual IRI runs. On a heavily distressed road with high lateral variability, you may have to do 5 – 10 – 20 passes until you see the roughness average begin to stabilize.

Very smooth roads have less distress, resulting in lower lateral variability, which translates to less difference in IRI values between runs. This means that on smoother roads, you are able to obtain a stable IRI average with far fewer runs because the path you drive has little effect on the results. For example, the table below shows data that was simultaneously collected using TotalPave IRI and an ARRB Hawkeye Class 1 Profiler on the same section of road to compare results between the two technologies. The road segment used for testing was extremely smooth with very little lateral variability, three runs were collected using each technology. Note that the IRI values reported for the Hawkeye profiler are an average of the left and right wheel path sensors.

| Run | TotalPave IRI (m/km) | ARRB Hawkeye (m/km) |

| RUN 1 | 0.59 | 0.58 |

| RUN 2 | 0.59 | 0.58 |

| RUN 3 | 0.58 | 0.58 |

The IRI values are relatively the same regardless of the path driven or technology used because the road surface exhibited very little lateral variability.

Collecting IRI for Asset Management Purposes

Traditional laser profilers are used by consulting firms to collect IRI for use in road asset management plans. Generally speaking, only one single IRI run is collected in a single lane for a single direction for every segment in the network in order to reduce data collection costs. The IRI values collected by these laser profilers are extremely precise, but would a single IRI value used to represent the entire width of the section be an accurate representation of the actual roughness of the entire road surface?

There can be extreme lateral variability within a single lane on rougher sections of road as shown above. Now imagine how different other lanes or lanes in the opposite direction could be. A single pass in a single direction may be adequate to get a relatively accurate representation of roughness on an extremely smooth highway segment, but municipal and county roads generally exhibit higher levels of random distress, equating to more lateral variability on the road surface meaning more passes are necessary to get an accurate representation of roughness.

TotalPave has been compared to traditional equipment many times. Overall the expected precision of an IRI value collected using TotalPave is within about 10% of a Class 1 laser profiler. This means that all things being equal, controlling for lateral variability and other random sources of error, in a one-to-one comparison a single IRI value collected with TotalPave should be within 10% of the Class 1 profiler.

These tests are performed to evaluate precision, but in the real-world we are more interested in the accuracy of the data. In other words, does the IRI data being reported accurately reflect the roughness of the entire road’s surface. Traditional profiler’s may be more precise than TotalPave, but a smartphone based platform like TotalPave IRI has a leg up on traditional profilers when it comes to collecting accurate IRI data due to low data collection costs. Lower costs and ease of use allow users of smartphone based platforms to easily collect multiple passes on a road segment, covering all lanes and directions if they wanted, in order to get a representative average IRI of the road segment’s entire surface.

TotalPave user’s simply need to mount their phone to the windshield of their vehicle, press a big green button on the app and drive. The app handles data collection completely automatically meaning the user can passively collect IRI if they wish. In fact, when TotalPave staff are carrying out PCI assessments for clients, we passively collect IRI whenever we are travelling around the study area. At minimum we like to get at least one IRI value per segment of road to meet the same standard that traditional profiler’s hit, but at the end of a project many segments in a network could have upwards of 5-10 individual IRI values that were collected passively throughout the project.

The more slices of road “sampled”, the more accurate average representation of the overall roughness of the road we obtain. A traditional profiler could technically also do multiple passes for each lane in each direction, but this would be cost prohibitive.

Comparing Two IRI Data Collection Technologies

It is critical to control for random sources of error when doing any scientific experiment. Here are the two largest sources of random error when attempting to compare two IRI data collection methods:

- Section start and end point

- Lateral variability in the road surface

Variability in the start point and end point of a section is an obvious source of error. If the start or end point for one method is different from the other method, you are essentially profiling two different segments of road. Relying on human input to start and stop data collection at a physical point along the road (for example a telephone pole, or the end of guide rail), is not adequate due to poor reaction time. Average human reaction time is around 0.25 seconds, if you’re travelling at 22m/s (80km/h) that means there’s at minimum an error of 5 – 6 meters at the start and end point if you are relying on visual queues along the side of the road.

TotalPave is able to automatically map IRI data to GIS centrelines, so the concern over start and end point is not an issue. If we are comparing data with a laser profiler, we simply obtain the GPS coordinates from where the profiler collected data, then map lines in the TotalPave system that exactly match.

Lateral variability in road surface is something that is trickier to control for. The best way to do so is to use a closed test track specifically designed to produce set IRI values regardless of the path you are driving. The test tracks are split into segments, each segment is monitored on a regular basis and consistently produces a known IRI value. Unfortunately, test tracks like this are exceptionally rare so having access to one is not realistic.

The next best option to control for lateral variability is to perform the testing on a segment of road that is exceptionally smooth, like a stretch of highway that has been freshly paved. You need to attempt to drive the exact same path with both IRI data collection methods, and doing multiple runs with each setup is still necessary, but the lack of distresses means the effects of minor variations in path driven should be insignificant.

If you do not have access to a freshly paved highway, the least desirable option is to perform tests on the best condition road you have access to. Higher levels of roughness mean higher lateral variability, so in this case doing many runs with both methods is absolutely critical until the average roughness stabilizes. Observing a difference between the two methods after only a few runs does not mean the actual methodologies are producing different results, it likely means that the road surface has significant lateral variability and you’ll need to do additional runs with each method until you obtain a stable average.

Comments (0)